Mordohar PIF type

日本語

中文

英語

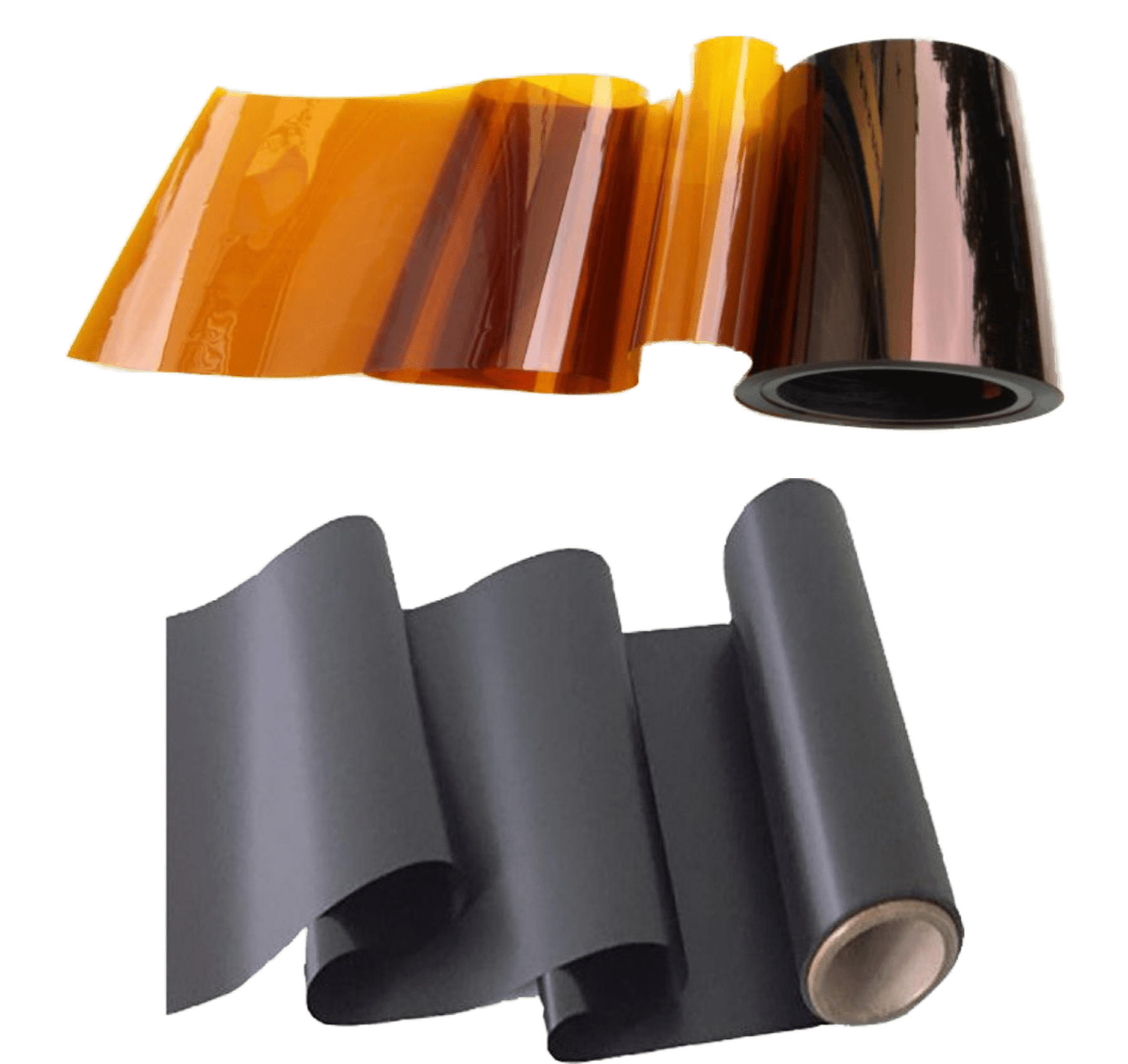

ポリイミドフィルムPIF

高性能、高付加価値商品です。化学性、物理性、電気性、耐放射線性を備えています。そして、耐熱性は抜群です。様々な厳しい作業環境に適用することができます。温度範囲は-452℉(-269℃)から+500℉(+260℃)まで、最大の高温は+752℉(+400℃)に耐えることができます。

応用

1. 発電機、ワイヤーとケーブル、コンデンサなどの絶縁材料。

2. 耐熱テープの最下層、例えば、感圧接着剤とF46 (FEP)。

3. フレキシブルプリント基板(F-PCB)の絶縁層に適用します。

4. ICパッケージング用耐熱フィルム。

品名表

| 品名 | 厚み | 幅 | 長さ(定尺) |

|---|---|---|---|

| PIF100 | 4mil / 100μ | 250 / 520 | 300 |

| PIF125 | 5mil / 125μ | 250 / 520 | 300 |

| PIF150 | 6mil / 150μ | 250 / 520 | 200 |

| PIF175 | 7mil / 175μ | 250 / 508 | 200 |

| PIF200 | 8mil / 200μ | 250 / 508 | 200 |

| PIF225 | 9mil / 225μ | 250 / 508 | 100 |

包裝 : 1 ~ 50 Kg/carton.

| 項目 | 単位 | PIF025 PIF050 |

PIF075 PIF100 |

PIF125 PIF150 |

PIF175 PIF200 |

PIF225 | 測定方法 |

|---|---|---|---|---|---|---|---|

| 厚み | μm | 25±10% 50±10% |

75±10% 100±10% |

125±10% 150±10% |

175±10% 200±10% |

225±10% | MTC |

| 密度 | g/cm3 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | ASTM D1505 |

| 寸法の安定性 | % | ±0.2 | ±0.2 | ±0.2 | ±0.2 | ±0.2 | IPC-TM-650 |

| 抗張力 | Kg/mm2 | ≧12 | ≧12 | ≧10 | ≧10 | ≧10 | ASTM D882 |

| 延伸率 | % | ≧ 50 | ≧ 40 | ≧ 40 | ≧ 40 | ≧ 40 | ASTM D882 |

| 絶縁破壊電圧 | KV | ≧5 | ≧9 | ≧10 | ≧11 | ≧12 | ASTM D149 |

| 誘電率 | -- | < 4 | < 4 | < 4 | < 4 | < 4 | ASTM D150 |

| 誘電正接 | -- | ≦1*10-2 | ≦1*10-2 | ≦1*10-2 | ≦1*10-2 | ≦1*10-2 | ASTM D150 |

| 体積抵抗率 | Ω cm | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ASTM D257 |

| 表面抵抗率 | Ω | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ASTM D257 |

| 吸水率 | % | ≦ 2.8 | ≦ 2.8 | ≦ 2.8 | ≦ 2.8 | ≦ 2.8 | IPC-TM-650 |

聚酰亚胺薄膜 PIF

是一种高性能、高附加值的产品。它具有耐化学、物理、电气和辐射性能。并且具有优良的耐热性。可适用于各种恶劣的工作环境。温度范围从-452℉(-269℃)到+500℉(+260℃),最高可承受+752℉(+400℃)的高温。

应用

1、发电机、电线电缆、电容器等的绝缘材料。

2. 耐热胶带底层,如压敏胶、F46(FEP)。

3.应用于柔性印刷电路板(F-PCB)的绝缘层。

4、IC封装用耐热膜。

产品名称列表

| 产品名称 | 厚度 | 宽度 | 长度(标准尺寸) |

|---|---|---|---|

| PIF100 | 4mil / 100μ | 250 / 520 | 300 |

| PIF125 | 5mil / 125μ | 250 / 520 | 300 |

| PIF150 | 6mil / 150μ | 250 / 520 | 200 |

| PIF175 | 7mil / 175μ | 250 / 508 | 200 |

| PIF200 | 8mil / 200μ | 250 / 508 | 200 |

| PIF225 | 9mil / 225μ | 250 / 508 | 100 |

包裝 : 1 ~ 50 Kg/carton.

| 物品 | 单元 | PIF025 PIF050 |

PIF075 PIF100 |

PIF125 PIF150 |

PIF175 PIF200 |

PIF225 | 测量方法 |

|---|---|---|---|---|---|---|---|

| 厚度 | μm | 25±10% 50±10% |

75±10% 100±10% |

125±10% 150±10% |

175±10% 200±10% |

225±10% | MTC |

| 密度 | g/cm3 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | ASTM D1505 |

| 尺寸稳定性 | % | ±0.2 | ±0.2 | ±0.2 | ±0.2 | ±0.2 | IPC-TM-650 |

| 抗拉强度 | Kg/mm2 | ≧12 | ≧12 | ≧10 | ≧10 | ≧10 | ASTM D882 |

| 拉伸比 | % | ≧ 50 | ≧ 40 | ≧ 40 | ≧ 40 | ≧ 40 | ASTM D882 |

| 击穿电压 | KV | ≧5 | ≧9 | ≧10 | ≧11 | ≧12 | ASTM D149 |

| 介电常数 | -- | < 4 | < 4 | < 4 | < 4 | < 4 | ASTM D150 |

| 损耗角正切 | -- | ≦1*10-2 | ≦1*10-2 | ≦1*10-2 | ≦1*10-2 | ≦1*10-2 | ASTM D150 |

| 体积电阻率 | Ω cm | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ASTM D257 |

| 表面电阻率 | Ω | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ASTM D257 |

| 吸水率 | % | ≦ 2.8 | ≦ 2.8 | ≦ 2.8 | ≦ 2.8 | ≦ 2.8 | IPC-TM-650 |

polyimide film PIF

It is a high-performance, high-value-added product. It has chemical, physical, electrical and radiation resistance. And it has excellent heat resistance. It can be applied in various harsh working environments. The temperature range is from -452℉(-269℃) to +500℉(+260℃), the maximum high temperature can withstand +752℉(+400℃).

Application

1. Insulating materials for generators, wires and cables, capacitors, etc.

2. Bottom layer of heat resistant tape, eg pressure sensitive adhesive and F46 (FEP).

3. Apply to the insulating layer of the flexible printed circuit board (F-PCB).

4. Heat resistant film for IC packaging.

Product name list

| Product name | Thickness | Width | Length (standard size) |

|---|---|---|---|

| PIF100 | 4mil / 100μ | 250 / 520 | 300 |

| PIF125 | 5mil / 125μ | 250 / 520 | 300 |

| PIF150 | 6mil / 150μ | 250 / 520 | 200 |

| PIF175 | 7mil / 175μ | 250 / 508 | 200 |

| PIF200 | 8mil / 200μ | 250 / 508 | 200 |

| PIF225 | 9mil / 225μ | 250 / 508 | 100 |

Package : 1 ~ 50 Kg/carton.

| item | unit | PIF025 PIF050 |

PIF075 PIF100 |

PIF125 PIF150 |

PIF175 PIF200 |

PIF225 | Test Method |

|---|---|---|---|---|---|---|---|

| Thickness | μm | 25±10% 50±10% |

75±10% 100±10% |

125±10% 150±10% |

175±10% 200±10% |

225±10% | MTC |

| Density | g/cm3 | 1.4 | 1.4 | 1.4 | 1.4 | 1.4 | ASTM D1505 |

| Dimensional Stability | % | ±0.2 | ±0.2 | ±0.2 | ±0.2 | ±0.2 | IPC-TM-650 |

| tensile strength | Kg/mm2 | ≧12 | ≧12 | ≧10 | ≧10 | ≧10 | ASTM D882 |

| Elongation | % | ≧ 50 | ≧ 40 | ≧ 40 | ≧ 40 | ≧ 40 | ASTM D882 |

| Dielectric Breakdown Voltage | KV | ≧5 | ≧9 | ≧10 | ≧11 | ≧12 | ASTM D149 |

| permittivity | -- | < 4 | < 4 | < 4 | < 4 | < 4 | ASTM D150 |

| loss tangent | -- | ≦1*10-2 | ≦1*10-2 | ≦1*10-2 | ≦1*10-2 | ≦1*10-2 | ASTM D150 |

| Volume Resistivity | Ω cm | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ASTM D257 |

| Surface Resistivity | Ω | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ≧ 1*1012 | ASTM D257 |

| Moisture Absorption | % | ≦ 2.8 | ≦ 2.8 | ≦ 2.8 | ≦ 2.8 | ≦ 2.8 | IPC-TM-650 |